Working the Left elevator now. The Frame has come together nicely with the exception of the Trim Spar at the rear of the elevator. This is the piece which will hold on the trim tab. Getting into a rhythm when dimpling all parts I missed the instruction where the top of this part was supposed to be machine counter synced. I called VAN's tech support. They told me to use my squeezer set to straighten the holes out again and then counter sync. I did this however when installing the skin I found the the part causes the skin to be wavy. I ended up counter syncing to far through the material in attempts to make the skin lay flat. Rather than having this be a weak bond for the trim tab I have ordered a new trim tab spar to try again.

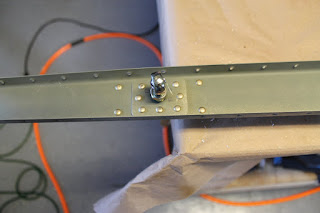

here is a pic of the spar that I messed up on.

the holes have become way to large and distorted as a result of my over counter syncing.

So as I wait for the replacement part, I will start on the Firewall parts. Here are some other parts of the frame and elevator trim servo going into place.

Hinges going in

flush rivets for joining the lower rib.

Trim servo mounting bracket

Trim Servo mounted to bracket