This week I have been working on the Canopy slider frame. Actually it has been a couple of weeks

This frame is what forms the actual canopy door to enter and exit the aircraft. The first item to start with is the roller assembly. This was a small challenge because the brass bushings the the rollers ride on appeared to be two short. According to the plans they were supposed to be 1/2 inch. The ones included were only 1/4. I ended up finding a suitable replacement at Ace Hardware, a 1 inch bronze which I cut and sanded down on the drill press. Sorry, as I did not take any pictures except this finished product. You can see the spare bronze bushing off to the right in this pic.

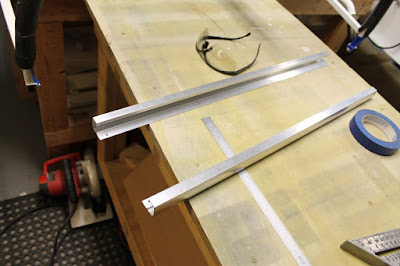

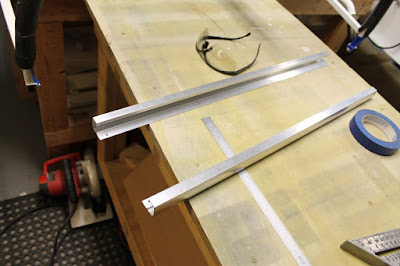

Next I cut the tracks down to size. Simple chop off with the hack saw.

The rear of the slider frame is supported by a plastic material block. The hole through the block and the metal bracket had to be located and drilled freehand. I took a lot of time alternating between the drill press and the 12 inch drill to make this line up perfectly. I wanted to make sure this was straight as this is a piece that could bind and cause the canopy to be hard to open and close.

Next the rear track. Another job for the drill press, vice and many clamps.

Finished product attached to the plane.